IRPC Americas: How Merichem's LO-CAT process helps Eni meet EU targets

By Adrienne Blume, Executive Editor, Hydrocarbon Processing

The concluding session of Track 2 of IRPC Americas ONLINE on September 23 examined small-scale sulfur recovery at two Italian biorefineries. Bill Echt, Business Development Manager for Merichem, talked about the company's LO-CAT process, which removes H2S from gas streams. The process is used by Italian refiner Eni at its Venice and Gela biorefineries.

Eni is a signatory to the EU Renewable Energy Directive. Eni meets its commitments for reductions in GHG emissions and energy use by using vegetable oils and biomass feedstock at its Venice and Gela biorefineries. Eni's Ecofining process is used at the biorefineries to convert biomass and oils into green fuels.

The design basis of the plants is to remove 99.9% of sulfur before CO2 is rejected to atmosphere, but operating conditions vary, creating a wide range of H2S concentrations and CO2 volumes leaving the downstream amine units. A highly flexible sulfur recovery process is needed to account for the range of feed gas conditions.

Eni uses Merichem's LO-CAT process at its biorefineries to remove sulfur. LO-CAT is an aqueous-based, ambient temperature process that converts H2S in any gas stream to elemental sulfur. It uses a chelated iron catalyst and features removal efficiencies of 99.9+%. LO-CAT, which is best suited for sulfur removal of > 1 tpd and < 20 tpd, does not result in any loss of sulfur removal efficiency at turndown conditions, and there is no minimum H2S concentration required.

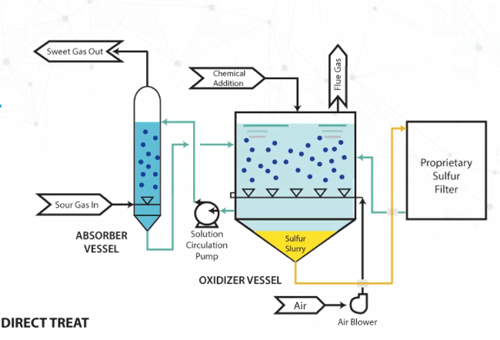

Figure 1. Direct treatment processing scheme

An autocirculation process is in use for processing non-combustible gas streams at the Gela refinery, while a direct treatment processing scheme (see Figure 1) is in place at the Venice refinery for treating combustible gas streams and product streams that cannot be exposed to air. Specialized equipment configurations accommodate the plants' sulfur removal requirements. The LO-CAT process is guaranteed to meet the required environmental specifications for the EU Renewable Energy Directive at the Venice and Gela biorefineries.

Comments