100 years of Uhde: thyssenkrupp’s chemical plant engineering business celebrates centenary

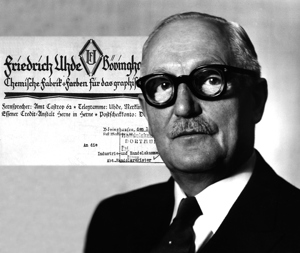

The Chemical & Process Technologies business unit of thyssenkrupp Industrial Solutions AG celebrated a milestone in 2021. It is one hundred years since engineer and entrepreneur Friedrich Uhde laid the foundation stone for a global success story on April 6, 1921.

Now, in this centenary year, the origins of the firm are to become visible in its name again: thyssenkrupp is changing the business unit’s name to thyssenkrupp Uhde. Uhde is a protected brand name that resonates across the global engineering sector to this day.

Sami Pelkonen, CEO Chemical & Process Technologies / thyssenkrupp Uhde: “For 100 years, the name Uhde has stood for innovation, quality, and reliability. It makes me particularly proud that our core technologies – such as ammonia synthesis together with water electrolysis – can now, with green hydrogen and green ammonia, make a key contribution to a sustainable future. So it’s really fitting that we’ll shortly be known as thyssenkrupp Uhde again.”

Company history Friedrich Uhde set up his engineering firm in Dortmund-Bövinghausen – in fact in a barn on his parents-in-law’s farm. Operating in an extremely challenging sector, this small local “start-up” was soon to grow into a global player. Today employing around 4,500 people worldwide, the company has stayed true to its roots and remains headquartered in Dortmund.

After its foundation in 1921, the company soon began to focus on ammonia synthesis, and fertilizer plants remain one of its main areas of business. The enterprise quickly expanded. In 1930 a subsidiary was established for high-pressure technologies which as part of thyssenkrupp now goes by the name Uhde High Pressure Technologies. In 1952 the then Uhde GmbH was acquired by Hoechst AG and in 1996 by Krupp AG, which merged into thyssenkrupp in 1999. In 2014 it was combined with other plant engineering businesses to form thyssenkrupp Industrial Solutions. The core of the former Uhde company is now the Chemical & Process Technologies business unit.

From green chemicals to bioplastics The first ammonia plant using the Mont-Cenis-Uhde process went into operation in 1928 and had a production capacity of 100 tons per day. Today the company can build plants with capacities of up to 5,000 tpd. Using “green hydrogen” produced by water electrolysis with renewable energy, the entire process is virtually CO2-free. “Green ammonia” is then made from green hydrogen in combination with nitrogen, which is simply captured from the atmosphere. So no fossil raw materials are involved at all. Ammonia is not only a base chemical, e.g. for the production of fertilizers, it is also a very good liquid energy carrier – and it can be used as a climate-friendly marine fuel. This means green energy from sunny and windy regions or from hydropower can be transported over long distances and subsequently reconverted or used as a chemical feedstock.

To make “green hydrogen”, water electrolysis technology from thyssenkrupp Uhde Chlorine Engineers (tk UCE) offers everything needed for the industrial-scale production of hydrogen from renewable energy. The company is a joint venture with Industrie De Nora and world market leader in industrial-scale electrolysis – originating from Uhde’s electrolysis business. tk UCE’s established technology and supply chain together with experience gained from several hundred electrolysis plants is now being used successfully for water electrolysis.

thyssenkrupp Uhde offers further future technologies for the climate turnaround. They include leading processes for carbon capture and utilization, e.g. for the production of methanol or synthetic natural gas (SNG). EnviNOx® technology for the reduction of emissions from nitric acid plants already saves more than 15 million metric tons of CO2 equivalents per year. Uhde also offers processes for the recycling of plastics and the production of PLA bioplastics.

Comments