Accelerating electrification with the “Cracker of the Future” consortium

the “Cracker of the Future” consortium announced two new members and accelerating the development of a game-changing technology for the electrification of the steam cracking process. This enables a revolutionary decrease in greenhouse gas emissions.

The consortium announced two new member companies: Repsol and Versalis (Eni) have recently joined the consortium. Together with founding members[1] Borealis (member of the OMV Group), BP, and TotalEnergies SE, the consortium covers ~1/3 of the European Union’s steam cracking capacity[2] with units in Austria, Belgium, Finland, France, Germany, Italy, Portugal, Spain, and Sweden.

The consortium looked broadly for the best technologies and understands their potential, development status, and needs:

There is a wide variety of possible electricity-based heating technologies, each offering its advantages, opportunities, disadvantages, and risks. The consortium has assessed many electricity-based heating technologies. It has selected a few for deeper dives to evaluate their development status and discuss potential cooperation with technology and equipment providers.

Moving towards testing this game changing technology:

The consortium is currently evaluating different technology opportunities and will soon announce one of our preferred highly promising options while a few other promising concepts need further assessment before we can come to a decision. Such a progressive funneling of opportunities allows the consortium to elect the most promising technologies quickly, while maintaining space for potential new promising developments.

In the scenario aimed at, and with public innovation support, a demonstration can be undertaken in 2023, and commercial availability could be delivered as early as 2026. The availability of sufficient affordable renewable electricity (and infrastructure) is key for commercial deployment.

Crackers are essential for the chemical industry and society:

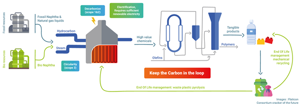

Steam crackers convert naphtha or natural gas liquids into basic building blocks (including ethylene, propylene, and aromatics), the start of many chemical value chains. However, the conversion requires a significant amount of energy and is conducted in furnaces at about 850 degrees Celsius, typically achieved by the combustion of fossil fuels. The building blocks are converted into a large variety of chemical products, delivering the functionality for our way of life ranging for instance from medical applications, to packaging to protect food, and polymers in wind turbines, solar panels, batteries and light-weighting of cars.

Electric cracking is a giant leap towards a climate-neutral Europe:

European Crackers are currently annually emitting ~30 Mton of CO2 (~20-25% of the European Chemical Industries’ overall greenhouse gas emissions[3]). The majority of these emissions originate from the crackers' furnaces. In combination with other electrification measures, electric cracking with renewable energy can eliminate the cracker's greenhouse gas emissions to a large extent.

Electric cracking enables key process routes for the circular economy:

Currently, European crackers predominantly operate on fossil-naphtha feedstock with some light feedstock such as LPG and ethane originating from refining of oil and from natural gas liquids. Electric crackers will also be able to convert bio naphtha and pyrolysis oil from waste plastics (chemical recycling) and thus enable key process routes for the circular economy.

Delivering electric cracking requires public-private partnership:

Meeting Europe’s Green Deal and becoming climate-neutral and circular requires enormous and disruptive changes. Developing electric cracking is one of the key changes. More than ever, a public-private partnership will be essential to achieve the objectives.

Brightlands Chemelot Campus will continue to coordinate the consortium

The olefin producing companies mentioned above deliver resources and their expertise in the consortium. Brightlands Chemelot Campus provides process- and content-support.

Comments