Siemens Energy partners with ProFlex Technologies

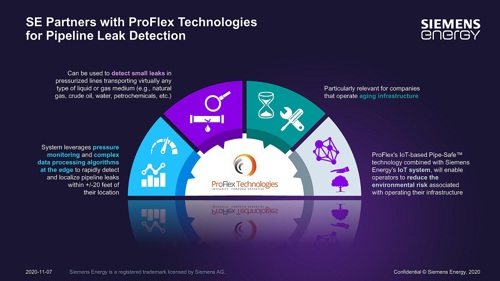

Siemens Energy has partnered with Houston-based ProFlex Technologies to

provide spontaneous leak detection services for pipeline operators. As part of

the agreement, Siemens Energy gains exclusive access to ProFlex Technologies’

digital Pipe-Safe™ advanced leak detection technology. The technology,

combined with Siemens Energy’s Internet of Things (IoT) system, will enable

operators to reduce the environmental risk associated with operating their

infrastructure by minimizing unplanned releases of product into the ecosystem.

The solution leverages remote pressure monitoring and complex data

processing algorithms to rapidly detect and localize pipeline leaks within +/-20

feet of their location. It is particularly relevant for companies that operate

aging infrastructure, enabling detection of small leaks in pressurized lines

transporting virtually any type of liquid or gas medium (e.g., natural gas, crude

oil, water, petrochemicals, etc.). Specific applications include long-distance oil and

gas transmission lines (i.e., multi-node systems); production gathering networks at

well sites; and offshore production risers.

“The use of Siemens Energy’s IoT technology, together with the Pipe-Safe

technology, is a powerful combination that will help operators safely operate

their assets and mitigate against the impact of unplanned product release

through the early detection of leaks,” said Nico van Rensburg, head of Onshore

Solutions’ Digital Solutions and Portfolio Innovation at Siemens Energy. “The

IoT-based leak detection solution uses highly sensitive pressure sensors

connected to pipelines at key locations to monitor internal pressure

continuously.”

Using complex data processing algorithms at the monitoring nodes, pressure

pulses created by the leak are identified, and leak location can be accurately

determined. This data can be transmitted to mobile devices or back to a central

location using the latest cloud-based technology. Immediate actions can be

taken to repair the leak. The IoT-based approach has broad applicability and is

suitable for use with any asset type, including new installations and existing

assets.

“Combining state of the art remote pressure monitoring and data processing

technologies within Siemens Energy’s IoT systems represents a cost-effective

leak detection solution that’s easy to install and requires little ongoing human

intervention,” said Stuart Mitchell, managing partner, ProFlex Technologies.

“The solution provides peace of mind to customers that any unexpected

damage to their pipeline can be immediately detected and located,

significantly reducing the volume of any liquid spill and the associated impact

to ongoing operation.”

“The Pipe-Safe solution from Pro-Flex Technologies complements our existing

IoT digital service offerings that, with the use of analytics, improve asset

efficiency and safety with greater operational transparency,” said Jennifer

Hooper, senior vice president, Industrial Applications Solutions for Siemens

Energy. “This collaboration represents yet another step on our journey to

helping the industry enhance sustainability by providing solutions that reduce

emissions and minimize environmental impacts.”

The spontaneous leak detection as-a-service is immediately available from

Siemens Energy, with the first implementations expected early next year.

Comments