2021 AFPM Summit Virtual Edition: Collaborating on Operating Limits panel discusses if Reliability Operating Limits can be exceeded temporarily

ADRIENNE BLUME, Executive Editor, Hydrocarbon Processing

AFPM's Summit featured an in-depth, virtual panel discussion on Tuesday afternoon on the topic of collaborating on operating limits to maximize operational performance and asset reliability.

The discussion, which featured panelists Ziad Jawad of Phillips 66, Dustin Beebe of Emerson Automation Solutions, Stephen Gill of Sinclair Oil Corp. and Nicole Birchall of Marathon Petroleum Corp., was facilitated by Tim Olsen of Emerson Automation Solutions and Michael Barham of Marathon Petroleum Corp.

Stephen Gill explained how safe operating limits (SOLs), which are well-established process safety metrics, are related to asset performance. SOLs help prevent loss of containment events, and act as safeguards to ensure that operating limits are met. To run a fully mature SOLs program and maintain the health of these safeguards, metrics are required to track performance, any changes must be managed and periodic revalidations must be performed.

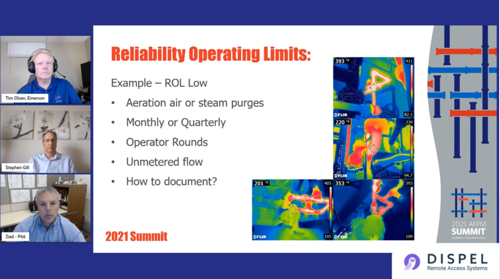

Ziad Jawad, a Senior FCC Engineer, discussed how reliability operating limits (ROLs) are similar to SOLs. ROLs cover operating windows for all equipment which goes beyond just API 584 on IOWs. Some of the concerns for such a broad category, Jawad explained, are that not all equipment is instrumented to provide automatic electronic data collection for refinery information systems such as DCS, LIMS, etc.

Also, general templates for ROLs must be adapted to specific ROLs for each piece of equipment, which can be difficult. Jawad gave an example of such ROL concerns, as shown (FIG. 1).

FIG. 1. Examples of ROLs.

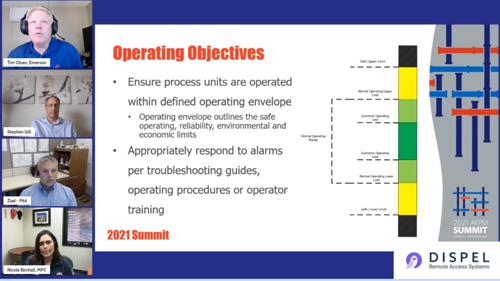

Nicole Birchall, an Operations Excellence Manager, next discussed how to keep operating limits within an operating envelope (FIG. 2). Normally, this is done with response to alarms outside of the outlined upper and lower operating limits. Sometimes, however, operations happen outside of this envelope, and a decision must be made as to whether or not operations can be allowed to run outside of the ROLs, and for how long.

FIG. 2. Sometimes, a decision must be made as to whether or not operations can be allowed to run outside of the ROLs, and for how long.

Dustin Beebe, a Vice President of Performance Services, talked about process boundary management and how to collect and actively verify that process boundaries are known, documented and that process controls and safeguards exist to operate within the limits and maintain them.

Process boundaries are not always controlled by the owner, Beebe explained, and they are not always relational or viewable by others. Many different sources exist for process boundaries, including safety, product quality, environmental protection, equipment limits, operation/controllability, point/measurement, operating procedures, alarm parameters, alerts, SIS, P&IDs and operator displays.

The key challenges for operations, Olsen explained, are that they are tasked with optimizing yields using the feedstocks available and given time limits, but ROLs in place may challenge where operations wants to operate. Agreements must be made on the boundaries associated with these limits, and the tolerable time (if any) for operating beyond the ROLs. Also, the quality and relativity of each limit must be agreed upon and ensured.

The AFPM Summit continues through Wednesday. To access news and editorial from the AFPM Summit, visit the Conference News tab on the homepage of www.HydrocarbonProcessing.com.

Comments