ExxonMobil introduces low viscosity Vistamaxx polymers to improve processing

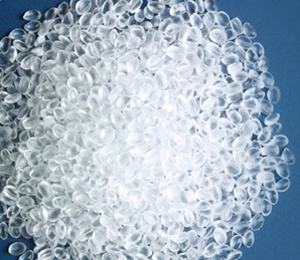

ExxonMobil is introducing low viscosity Vistamaxx performance polymers that can be used to maintain or improve cycle times of injection molded or extruded applications. Vistamaxx 8880 improves the flow and processing of polyolefin compounds which contain Vistamaxx 6202 or 6502, or are heavily filled.

“Vistamaxx polymers are used for compound modification at dosage levels of 5% to 15% to enhance properties such as impact strength and clarity, while reducing stress whitening,” said Gertrud Masure, Vistamaxx market development manager, ExxonMobil Chemical. “For applications such as grips, however, dosage levels have to be much higher to achieve the required performance improvements which can result in longer cycle times.”

The introduction of low viscosity Vistamaxx 8880 can overcome this by offering equivalent cycle times.

“Compounders can now tailor processing and end-use product performance even more by using Vistamaxx 8880 to modify viscosity,” said Masure. ”They can achieve product improvements by including Vistamaxx 6202 and 6502 in their formulations, while processing performance can be maintained or enhanced by using low viscosity Vistamaxx 8880 in the same formulations.”

For compounders, adding Vistamaxx 8880 to a formulation enhances the molding process by reducing injection pressure due to its low viscosity and cooling efficiency. With controlled cooling temperature, cycle times can be achieved that are comparable to styrene-ethylene-butylene-styrene (SEBS) compounds used for soft thermoplastic elastomer (TPE) components such as grips and other soft-touch overmolding TPE applications.

Because Vistamaxx 8880 reduces compound viscosity it can enhance polyolefin blend properties to deliver better flexibility, increased impact resistance and improved aesthetics.

Reduced unit costs are possible due to the enhanced processing efficiency provided by Vistamaxx 8880 for compounding, injection molding and extrusion processes. Its enhanced flow can facilitate higher production rates leading to cost efficiencies during processing. Meanwhile, Vistamaxx 6202 and 6502 allow increased filler loadings for lower costs.

End-users can benefit from improved products, like non-slippery TPE grips or stay-flat carpet tiles. In TPE grips, Vistamaxx 6202 or 6502 improve surface quality by enabling soft-touch and a non-slippery feel due to oil-free compounds. Stress whitening can also be minimized. Costs can be reduced by up to 20% because filler loadings of up to 30% are possible. By adding Vistamaxx 8880 in the same formulation, comparable cycle times and higher flow are possible with the same tool.

In carpet tiles, Vistamaxx can be used to design a highly filled polyolefin solution as secondary backing, providing dimensional stability and flexibility to the end-use carpet. Lower costs are possible due to high filler loading capability, lower polymer density and recycling of scrap during manufacturing. The addition of Vistamaxx 8880 to a compound based on Vistamaxx 6202 or 6502 allows filler loadings to be increased further. It also enables excellent extrusion processability due to a high flow rate.

“Vistamaxx 8880 is symbolic of the possibilities that the Vistamaxx polymer portfolio can deliver,” said Masure. “It allows application or process innovation to be tailored to the benefit of compounders, brand owners and end-users.”

Comments