Schneider Electric Improves Time to Production, Reduces Device Commissioning Time with EcoStruxure Field Device Expert

FOXBORO, Mass. – Schneider Electric, the leader in the digital transformation of energy management and automation, released EcoStruxure™ Field Device Expert, an application that improves how engineers commission, configure and maintain field devices throughout the lifecycle of the plant. Field Device Expert’s Intelligent Commissioning Wizard completely automates detection, configuration, commissioning and testing of HART field instrumentation connected to an EcoStruxure Foxboro distributed control system (DCS). Automatic binding and configuration of HART devices

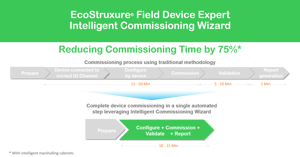

Traditional, manual device commissioning methodology is manpower intensive, making it error-prone, time-consuming and expertise dependent. By automating the configuration and commissioning process, Field Device Expert drastically changes automation project execution by minimizing hardware dependencies and custom engineering and offers more flexibility in the design, timing

As part of Schneider Electric’s EcoStruxure architecture and platform, Field Device Expert improves efficiency, safety, productivity

Now fully integrated into the Foxboro DCS, Field Device Expert’s new capabilities include:

- Data available in Field Device Expert can be utilized by EcoStruxure Maintenance Advisor, a predictive maintenance and decision-support platform that reduces configuration time and human error.

- Intelligent Commissioning Wizard enables faster time to production and reduced commissioning effort and time. With Intelligent Commissioning Wizard, engineers can commission devices 24/7 with no additional overtime cost.

- Device Replacement Wizard significantly reduces time and expertise by automating HART device replacement, either individually or in bulk. Even when a device is replaced with a non-alike device, the software automatically executes the replacement, significantly reducing downtime in such cases.

- Single Information Repository increases safety and security by eliminating costly errors. The valuable information created during each phase of device management is saved in a single database so it can be used throughout the lifetime of the devices. This unified database eliminates duplication and mismatch issues commonly experienced with independent DCS and asset databases. This also saves additional effort by providing a single, unified backup.

- Access Permissions for safety-related devices align with IEC61511-1, the prevailing industry standard that establishes best practices in the engineering of systems to ensure the safety of an industrial process using instrumentation.

- Bundled HART device description library enables faster device deployment, eradicates version mismatch, and eliminates cybersecurity risks previously created by moving documents from the HART consortium web page into the system. It also prevents users from browsing and downloading files from the Internet since engineers no longer need to search for them.

- FDT 2.0 compliant frame leverages the latest technologies (.NET over ActiveX/COM) and supports digital signatures to prevent tampering.

- Interoperability with any device, from any vendor, with any protocol. With Foxboro DCS interoperability and any-bus capabilities, users can maintain preferences because the system adapts to user choice.

- Advanced Diagnostic Support for vendor-embedded device type managers (DTM) enables maintenance technical personnel to access advanced diagnostics written specifically for the concerned device by its vendor. Field Device Tool (FDT)/device type manager enables

flexible user interface, rich graphics and comprehensive diagnostics for field devices, even complex devices such as positioners.

“We are committed to helping our customers reap additional value from their assets and process automation investments,” said Fouda. “Our goal is to help customers progress to a safe, secure digital operation in which they can gain control of all their critical business variables—safety, security, efficiency, reliability and, most importantly, profitability. Field Device Expert and Intelligent Commissioning Wizard are perfect examples of how we continue to help our customers convert their process automation systems and solutions into the profit engines of their businesses.”

[1] https://www.ey.com/Publication/vwLUAssets/EY-spotlight-on-oil-and-gas-megaprojects/$FILE/EY-spotlight-on-oil-and-gas-megaprojects.pdf

Comments